Milling machines are one of the most popular machines in mechanical processing workshops today. It is divided into two main types: horizontal milling machine and vertical milling machine. Each type has its own characteristics, suitable for certain applications. In the following article, AC TECH will point out the differences between these two types of machines, the advantages and disadvantages of each type to help you choose the right machine.

1. What is a horizontal milling machine?

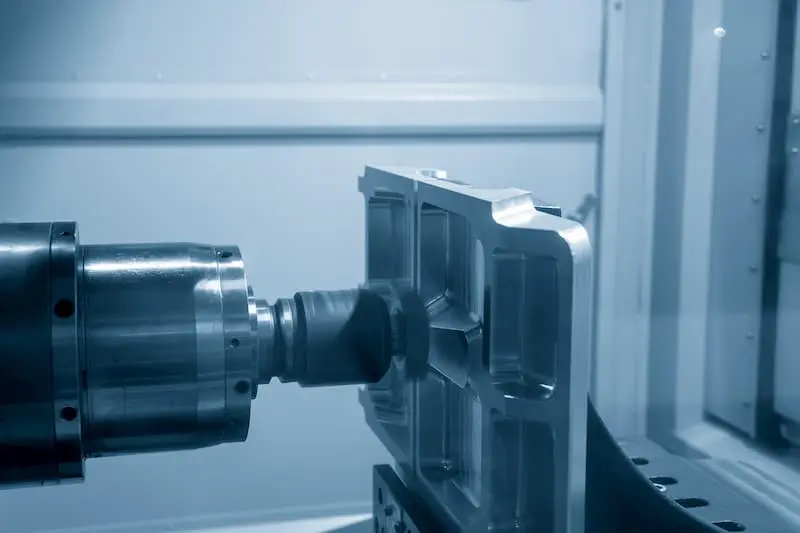

A horizontal milling machine is a machine with a main axis parallel to the machine table. On many horizontal milling machines, there is an additional scale table that allows milling at different angles. This type of machine is compatible with machining large, high-precision parts or machining large, multi-faceted parts.

Horizontal milling machines are often used to machine various planes, inclined planes and grooves. Some machines are equipped with additional motors for the machine table, allowing the workpiece to move synchronously with the shaft to support milling of spiral-shaped parts such as hypoid gears. This type of machine is suitable for processing heavy materials, large sizes, thicker or deeper grooves.

2. What is a vertical milling machine?

A vertical milling machine is a type of mechanical processing machine with a main shaft installed vertically, perpendicular to the machine table. This type of machine is compatible with many types of knives such as end mills, face mills, disc mills, etc. The machine has the ability to process quickly, helping to increase processing productivity for the factory.

Based on structure, vertical milling machines are divided into two types:

Consol milling machine: has a fixed main axis and a table that moves perpendicular and parallel to the main axis. This helps the milling cutter come into contact with the workpiece to perform the cutting process. The machine table moves along two XY axes. This type of machine is often used to process small parts.

Bed milling machine: has a very large table size, allowing the processing of large workpieces. The machine table of the bed milling machine only moves perpendicular to the main axis along the Y axis. Meanwhile, the main axis can move back and forth along the X axis and up and down along the Z axis.

3. Advantages and disadvantages of horizontal milling machines

3.1. Advantage

Better chip evacuation: the structure of the horizontal cutter supports better chip evacuation. Thanks to that, chip problems on the machine can be limited.

More stable operation: the horizontal milling machine’s structure is rigid, so it is less prone to vibration and misalignment than a vertical milling machine.

Higher machining productivity: thanks to good chip evacuation and stable operation, horizontal milling machines allow faster machining, helping to increase working efficiency.

Higher depth of cut: horizontal milling machines are capable of processing deeper cuts in a faster time than vertical milling machines.

Ability to process complex shapes: horizontal milling machines are capable of processing parts with complex shapes. For example, the spiral shape of hypoid gears.

Suitable for processing heavy and large workpieces.

3.2. Defect

Higher cost: investment costs and maintenance costs for horizontal milling machines are higher than for vertical milling machines. That’s why horizontal milling machines are more popular in large-scale enterprises.

More difficult to operate: due to the machine’s structural characteristics, horizontal milling machines require highly specialized people to operate.

4. Advantages and disadvantages of vertical milling machines

4.1. Advantage

Lower costs: investment and maintenance costs for vertical milling machines are not high. This allows both small and medium enterprises to invest in vertical milling machines in their production lines.

Easy to use: thanks to its compact design, providing good visibility for the operator, the vertical milling machine is considered an easy-to-use machine.

Diverse processing capabilities: vertical milling machines are capable of processing many materials according to many different requirements.

4.2. Defect

Lower machining productivity: compared to horizontal milling machines, vertical milling machines have lower material removal capabilities and cannot machine large workpieces. Therefore, vertical milling machines have lower processing productivity than horizontal milling machines.

Limited depth of cut: machining deep grooves is not an advantage of vertical milling machines. Therefore, a vertical milling machine will take longer to machine a deep groove than a horizontal milling machine.

5. Distinguish between vertical milling machines and horizontal milling machines

The following is a table comparing the highlights between vertical milling machines and horizontal milling machines:

Criteria Vertical milling machine Horizontal milling machine

Main axis direction Main axis is in vertical direction, perpendicular to machine table Main axis is in horizontal direction, parallel to machine table

Geometry of the milling cutter Usually, the cutter is long and thin cylindrical. The cutter is shorter and thicker, capable of cutting deeper and processing large workpieces

Machining characteristics More accurate when machining small parts, difficult to process deep cuts Easy to create deep cuts The machine operates smoothly, with little vibration or misalignment

Material removal ability Average material removal ability Good material removal due to good chip evacuation ability

Machining applications Suitable for single-sided machining, keyway machining with moderate depth Suitable for machining flat surfaces, bevels, deep grooves

Cost Investment and maintenance costs are average, small and medium enterprises can invest Investment and maintenance costs are quite high, suitable for large-scale businesses