In processing, mechanical materials must go through many stages to become a finished product. Among them, rough machining and finishing machining are the two most common and important stages. So, what are rough machining and finishing machining, how to differentiate? Let’s find out through the following article.

1. What is roughing?

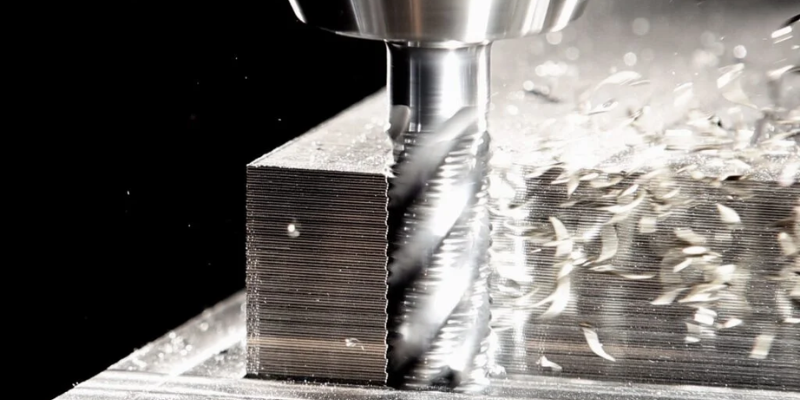

Roughing is a machining method that removes a large amount of excess material from the surface. This is to create a general shape for the part to be machined. Therefore, this method does not require high precision machined surfaces like other methods.

To remove a large amount of material, the machining process needs to be performed with a slow spindle speed, large cutting depth… This requires a strong machine and cutter with high rigidity. To increase machining productivity as well as reduce the load on the later finishing stage, you can consider using a CNC machine for the roughing stage because of the precision and machining stability of CNC machines.

2. What is finishing?

In contrast to rough machining, finishing machining is a machining method aimed at shaping the product according to requirements, producing a finished product according to production purposes.

In finishing machining, the spindle and cutter often run at high speed because the amount of material removed is small. This processing method produces products with high precision and smooth surfaces. This is the biggest difference between rough machining and finishing machining.

3. Distinguish between rough machining and finishing machining

Rough machining and finishing machining are distinguished through the following criteria:

Criteria Rough machining Finish machining

Purpose Removing large amounts of excess material Finishing the surface (smoothing, polishing), increasing the accuracy of processed products

Speed Slow knife speed, deep cuts Fast knife speed, small, shallow cuts

Product surface after processing High roughness, no aesthetics Glossy, smooth surface, high precision

Dimensional Accuracy Low Dimensional Accuracy High Dimensional Accuracy

When to do it: Done right in the first stage Only done when rough machining and semi-finishing machining have been completed

Above are some shares about two methods of rough machining and fine machining. Hopefully this information will help you choose the type of cutting knife and type of machinery suitable for your machining project.