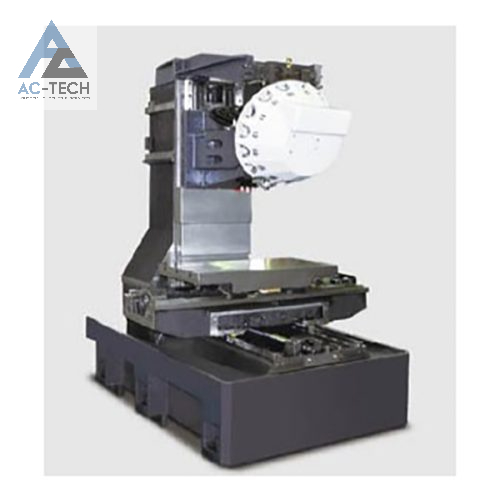

– By means of Finite Element Analysis and 3D dynamic simulation, our products have the optimum structure with which the best rigidity and accuracy can be obtained.

– The big span structure of Y axis wider juction between column and base provides the most stable.

– High speed A.T.C: Tool change time up to 1.6 sec. and highly reliable automatic tool change mechanism cooperated with rapid traverse of three axes shorten the machining time enhancing the output.

| ITEM / MODEL |

T500 |

T700 |

|---|---|---|

| X/Y/Z Axis travel |

510 / 430 / 330 mm |

700 / 430 / 330 mm |

| Table size |

560 x 400 mm |

850 x 400 mm |

| Spindle speed |

Direct drive 12000 rpm |

|

| Spindle taper (Tool shank) |

BT-30 |

|

| Max. loading capacity |

250 kg (Max. feed rate 60 m/min) |

|

|

350 kg (Max. feed rate 48 m/min) |

||

| X/Y/Z Axis rapid feed rate |

60 / 60 / 60 m/min |

|

| X/Y/Z Axis cutting feed rate |

30 / 30 / 30 m/min |

|

| Spindle motor (Mitsubishi) |

3.7 / 5.5 kW |

|

| X/Y/Z Axis servo motor (Mitsubishi) |

1.5 / 1.5 / 2.2 kW |

|

| X/Y/Z Axis positioning |

±0.004 mm |

|

| X/Y/Z Axis repeatability |

±0.002 mm |

|

| ATC type / Magazine No. |

Turret 16T (21T opt.) |

|

| Tool change time |

1.6 sec. |

|