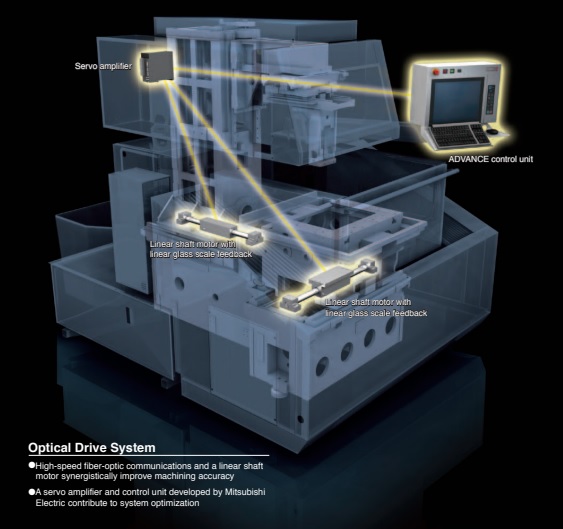

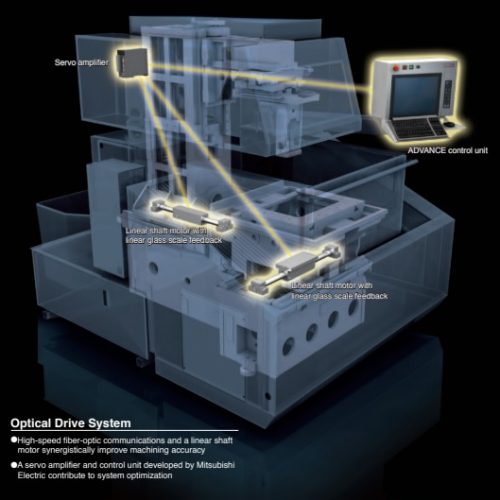

Next-generation drive system and optimum machine structure

* Equipped with a linear shaft motor(LSM)

* Circular accuracy within 1μ is realized using optical drive system(ODS).

Advanced technologies for greatly improved productivity

* New annealing system greatly improves wire threading with a curl ratio of less than 10%.

* Wire break point insertion is greatly improved for thick workpieces.

* Wire threading suitable for workpiece shape. (jet on/off and submerged break point insertion)

Advanced Productivity

* Surface roughness improvements are realized through enhanced power supply performance for high speed machining.

* Surface finish reduced by 50% by machining with only 2 cuts.

* Machining time comparison for Rz 3.5 μm/Ra 0.45 μm with 3 cuts.

| Specifications | MV1200S | MV2400S |

| Max Workpiece dimensions (W/D/H) | 810mm x 700mm x 215mm | 1,050mm x 820mm x 305mm |

| Wire Diameter | 0.1mm – 0.3mm | 0.1mm – 0.3mm |

| Table Dimensions | 640mm x 450mm | 840mm x 560mm |

| Machining Travel (X/Y/Z) | 400mm x 300mm x 220mm | 600mm x 400mm x 310mm |

| Machining Travel (U/V) | ±60mm x ±60mm | ±75mm x ±75mm |

| Max Taper Angle | 15º with 200mm workpiece thinkness | 15º with 260mm workpiece thinkness |

| Max Workpiece weight | 500 Kgs | 1,500 Kgs |

| Machine weight | 2,700 kgs | 3,500 kgs |